Impact sand making machine is an efficient and multifunctional crushing equipment, which is widely used in construction, roads, railways, mining, metallurgy and other fields.The following is a detailed introduction to the impact sand making machine:

I. Definitions and uses

Impact sand making machine, also known as impact crusher, is mainly used for crushing and shaping of soft or medium-hard and very hard materials. It is widely used in the crushing and processing of various ores, cement, refractory materials, alumina clinker, adamantine, glass raw materials, mechanism construction sand, stone and various metallurgical slag. Especially for silicon carbide, adamantine, sintered bauxite, American sand and other high hard, extra hard and wear-resistant and corrosive materials, the impact sand making machine shows higher output and efficiency.

II. Principle of operation

The working principle of the impact sand making machine is that the material enters the crusher from the feeding hopper, and the material is divided into two parts by the distributor. Part of the material from the middle of the distributor into the high-speed rotating impeller, the impeller is rapidly accelerated, the acceleration can be up to hundreds of times the acceleration of gravity, and then with a speed of 60-70 m / s from the impeller three evenly distributed flow channel projectile out. These high-speed thrown out of the material and the first by the distributor around the free fall of another part of the material impact crushing, and then together with the impact of the vortex branch cavity on the material lining, the material lining rebound, diagonally upward impact to the top of the vortex cavity, and then change the direction of its movement, the deflection of the downward movement. In this way, the material is subjected to many impacts, friction and grinding in the vortex crushing cavity, and finally crushed into the required particle size products.

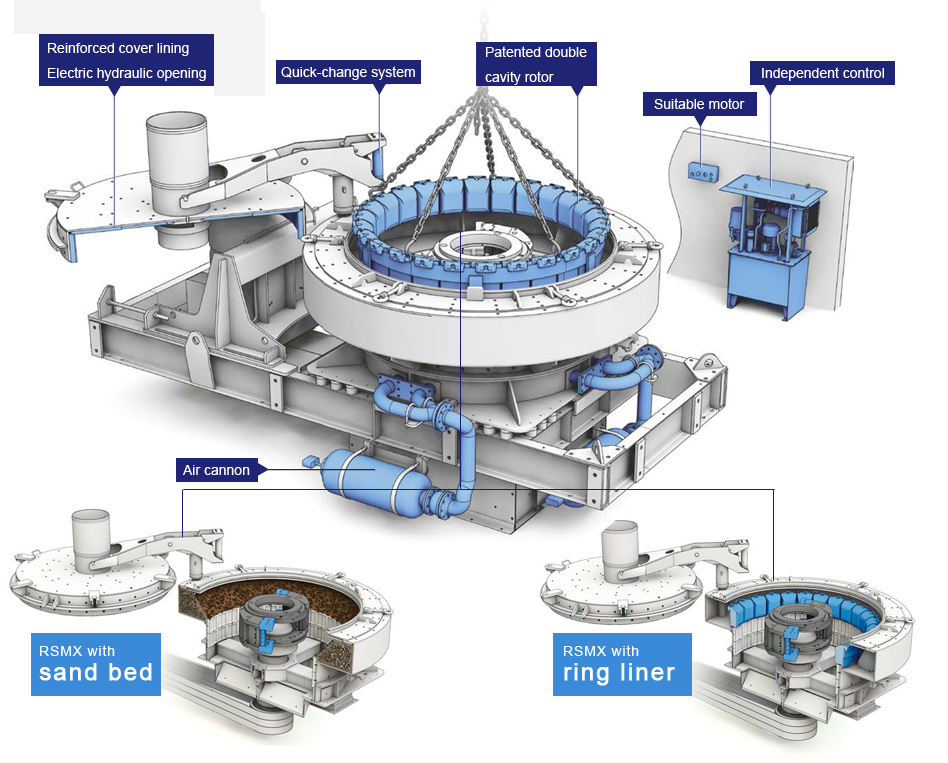

III. Structural components

The impact sand making machine is mainly composed of the following structural components:

- Bearings and transmissions: The impeller and crushing device are driven by the motor and the V-belt.

- pedestals: Generally in a quadrilateral shape, bearings are installed in the center, discharge devices are installed on both sides, and the motor is installed in the longitudinal part of the base.

- Lubrication system: Mainly lubricate the bearing parts, and use a specific oil pump to add them.

- Feed hopper: The transition device for the material to enter the crusher is usually wear-resistant.

- Vortex crushing chamber: An annular space composed of two cylinders is the main place for material crushing.

- Impeller: Made of special materials, the materials are evenly distributed and thrown out at high speed through high-speed rotation.

- Material sieve: The broken materials are sieved, the qualified materials are sent out, and the unqualified ones enter the crushing chamber for secondary crushing.

IV. Characteristics of the work

- Simple and reasonable structure, low operating cost: The impact sand making machine is reasonably designed, easy to maintain, and low operating costs.

- Low wear and high crushing rate: Use the principle of stone beating to reduce wear and improve crushing efficiency.

- Energy-saving, fine crushing, rough grinding function: It has the functions of fine crushing and rough grinding, and adapts to the processing needs of various materials.

- Less affected by the moisture content of the material: Can work normally in materials with high moisture content.

- Low noise and less dust pollution: The working noise is less than 75 decibels, the dust pollution is less, and it meets the requirements of environmental protection.

- The product is in excellent shape: The broken material has uniform particle size and excellent shape, which helps to improve the strength and durability of concrete and other products.

V. Areas of application

Impact sand making machines are widely used in construction, roads, railways, mining, metallurgy and other fields.It can efficiently break various rocks and stones into sand that meets building standards and is used in concrete production, pavement laying, road infrastructure construction and other projects.At the same time, in the fields of mining and metallurgy, impact sand-making machines can easily handle metal ores and slag of various hardness, providing a strong guarantee for subsequent smelting and processing.

VI. Maintenance

In order to ensure the normal operation and extend the service life of the impact sand making machine, regular maintenance is required.This includes checking whether the various components of the equipment are operating normally, removing sand, gravel and impurities inside the equipment, keeping the lubrication system clean and adequate, adjusting or replacing worn parts, etc.In addition, it is also necessary to pay attention to the vibration and noise of the equipment, and find and eliminate faults in time.

In summary, impact sand making machines play an important role in many industries because of their high efficiency and multi-function characteristics.Through continuous optimization and improvement, the performance of impact sand making machines will be even better, providing stronger support for the development of various industries.

Leave Message To Us

You can contact us by leaving a message or calling our sales hotline

Tip:

We would appreciate it if your information includes the equipment required, type of project, country of export, and budget amount so that you can get the most accurate quote!

Service Process: Enterprise Negotiation - Proposed Solutions - Production and Commissioning - Operational Production

Follow on Social