移动式破碎车,也称为移动式破碎机,是一种高效、灵活的破碎设备,广泛应用于建筑工地、矿山、公路施工等领域。以下是对移动式破碎车的详细介绍:

I. Definitions and uses

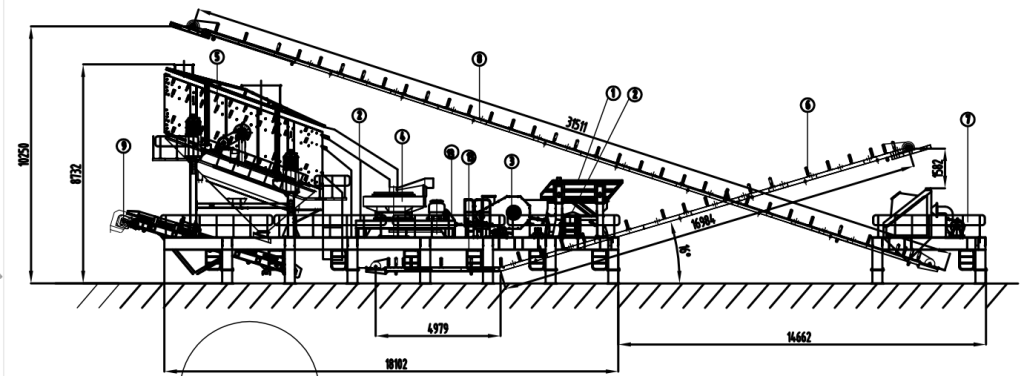

Mobile Crusher Truck is a kind of crushing equipment integrating feeding, crushing, screening and transportation functions, which can be flexibly moved to the vicinity of the raw materials to be crushed, and carry out in-situ crushing and screening operations. It is mainly used to process various hard rocks, ores, construction wastes and other materials, crushing them into the required size for the production of concrete, road paving and other projects.

II. Principle of operation

The working principle of the mobile crushing truck mainly includes the following steps:

- Feed: Raw materials are fed into the inlet of the mobile crusher through loading equipment such as loaders or excavators.The feeding system usually includes a vibrating feeder, which can evenly feed the raw materials into the crushing chamber.

- Broken: After the raw material enters the crushing chamber, the crushing system starts to work.The crushing system consists of components such as a crushing chamber, a crushing hammer (or crusher), and a crushing tooth plate (or crushing plate).The crushing hammer rotates at high speed to impact, impact and crush the raw materials, while the crushing tooth plate plays a role in guiding and controlling the particle size of the material.The broken material is discharged through the discharge port.

- Screening: The broken material is further sieved through devices such as conveyor belts or vibrating screening machines.Screening can divide the material into different particle sizes according to needs to meet different application requirements.

- Transport: The sieved material is transported to the next process link or storage area through equipment such as conveyor belts or stackers.The conveying system can realize continuous conveying and stacking of materials.

- Control: Mobile crushing trucks are usually equipped with a control system for monitoring and controlling the operating status and working parameters of the equipment.The operator can start and stop, adjust and troubleshooting the crusher through the control system.

III. Structural components

The mobile crusher is mainly composed of the following parts:

- Steel frame: Provide the overall support and stability of the equipment.

- Feeding system: Composed of a feeder, used to feed raw materials into the crusher.

- Crushing system: Including components such as crushing chamber, crusher and crushing tooth plate, it is the core part of the equipment.

- Conveying system: It consists of a conveyor belt, which is used to transport the broken material to the target location.

- Control system: Used to monitor and control the operation of equipment, realize automated operation and fault diagnosis.

IV. Types and configurations

There are many types of mobile crushers, the common ones include mobile jaw crushers, mobile impact crushers, mobile cone crushers and mobile sand making machines.Users can configure different equipment according to the type, scale and finished material requirements of the processed stone.

V. Strengths and characteristics

- High flexibility: It can be quickly moved to the vicinity of the raw materials that need to be broken, saving transportation costs and time.

- Small footprint: The equipment has a compact structure and is suitable for small construction site environments.

- High efficiency and energy saving: High crushing efficiency, low energy consumption, improved work efficiency and production quality.

- Easy to operate: The degree of automation is high, the operation is easy, and the labor intensity is reduced.

- Easy maintenance: The equipment has a simple structure and is easy to maintain and maintain.

VI. Areas of application

Mobile crusher trucks have a wide range of applications in construction sites, mines, highway construction and other fields. In the construction site, it can be used to deal with construction waste, waste concrete, etc., to realize the reuse of resources and environmental protection and emission reduction. In the field of mining, it can be used to crush and screen the ores, providing raw materials for subsequent mineral processing. In highway construction, it can be used for crushing roadbed materials, asphalt concrete, etc., to ensure the quality of road construction.

VII. Precautions for use

When using a mobile crusher, you need to pay attention to the following matters:

- Ensure that the equipment runs on a smooth and fixed basis to avoid excessive vibration or instability.

- Regularly check whether the various components of the equipment are operating normally, including oil pressure, electrical interlocking system, lubricating oil, instrumentation, etc.

- During the operation of the machine, personnel shall not approach the rotating surface of the crusher, and shall not stand in the rotating surface.

- During the work of the machine, personnel are not allowed to put their hands into the machine to take raw materials or other items.

- Pay attention to whether the tire pressure is normal (for tire-type mobile crushing vehicles), whether it is too high or too low will affect its service life.

- The equipment must be no-load when it is started, and there must be no materials in the machine.

Through reasonable use and maintenance, the normal operation and service life of the mobile crusher can be ensured.

Leave Message To Us

You can contact us by leaving a message or calling our sales hotline

Tip:

We would appreciate it if your information includes the equipment required, type of project, country of export, and budget amount so that you can get the most accurate quote!

Service Process: Enterprise Negotiation - Proposed Solutions - Production and Commissioning - Operational Production

Follow on Social